|

Cableway machines |

|

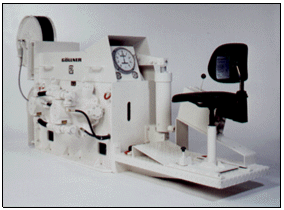

The cableway machine/hydraulic aggregate assembly is operated in a closed circuit as a hydrostatic remote gearing. Key technical data such as cable speed and tensile force are defined by the pumping capacity of the aggregate and the type and quantity of hydraulic motors used. All cableway machines are supplied with a control stand which has a seat for the operator from which the machine can be operated via single-lever controls and monitored. |

|

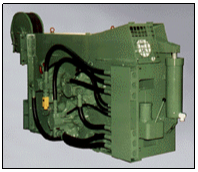

The drive plate is fitted with exchangeable segments made of plastic (grooved wheel winches) or hardened steel (parabolic winches). Double-jaw brakes with asbestos-free brake linings are used as safety brakes. The brake acts directly on the cable carrier and is closed and hydraulically vented by a coil spring via a brake cylinder. The incoming and outgoing cable is guided via adjustable cable guide rollers on the front of our winders. These can be adjusted laterally and pivoted around the cable axis. |

|

In order to reduce wear-induced cord tension, all grooved wheel winches are equipped with an after-twisting device. This facilitates simple, on-site mechanical reworking of individual grooves. |

|

Additional technical information about performance data for the GP series or performance data for the GR series are available on request. We are happy to make special arrangements to supply cableway machines which are not listed here. |

|

Göllner cableway machines serve as drives for all conveyors operating with circulating endless cables/ropes. This also includes cableways for the transportation of materials and persons. We offer the following versions:

· Cableway machine with parabolic disc (GP) · Cableway machine with grooved wheel (GR)

All cableway machines are modular and are operated with radial piston motors which are optionally available in clockwise/anti-clockwise versions. In conjunction with a Göllner hydraulic aggregate the cable speed is infinitely variable. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© 2006 Göllner Maschinenbau GmbH |